Rotary Screen Printing

Rotary screen printing is a type of printing identical to screen printing but used on all those products with a cylindrical surface such as bottles and glasses.

How does it work

The cylindrical screen printing machine rotates the product while the frame and squeegee slide in synchronization.

Some examples of application on promotional items

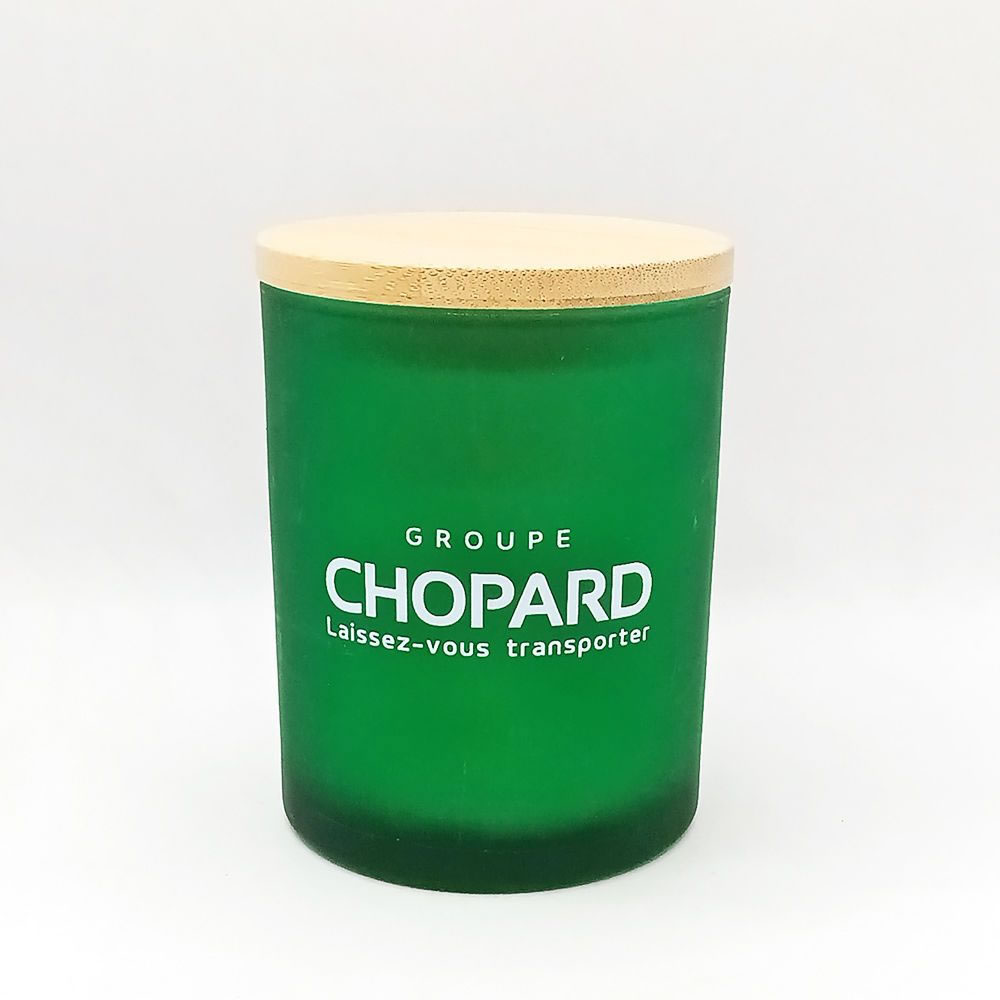

Rotary screen printing can be applied to many materials such as glass, ceramic, metal, wood, plastic and recycled plastic and is therefore suitable for printing candles, flasks, bottles, glasses, thermoses and cups.

Pros and Cons of Rotary Screen Printing

Pros

- It is economical, especially with large quantities;

- It is versatile, easily adapts to flat and circular surface products and can be applied to a wide range of materials;

- Deposits very thick layers of ink on almost any surface, creating a raised effect that is very pleasant to the touch;

- High coverage;

- The print is highly resistant to light, mechanical abrasion, therefore scratches, and humidity.

Cons

- Not suitable for reproducing writing or logos with details that are too small and thin;

- You cannot print more than one color;

- Screen printing does not reproduce shades.